Project objectives

Increasing recovery degree of PCB

Reducing the volume of unused PCB

Promoting the use of biotechnology

Reducing the environmental impact of processing the PCB

Reducing processing costs, CO2 emission and waste generation

Evaluating the technological and economic possibilities

Ensuring the efficient communication and dissemination

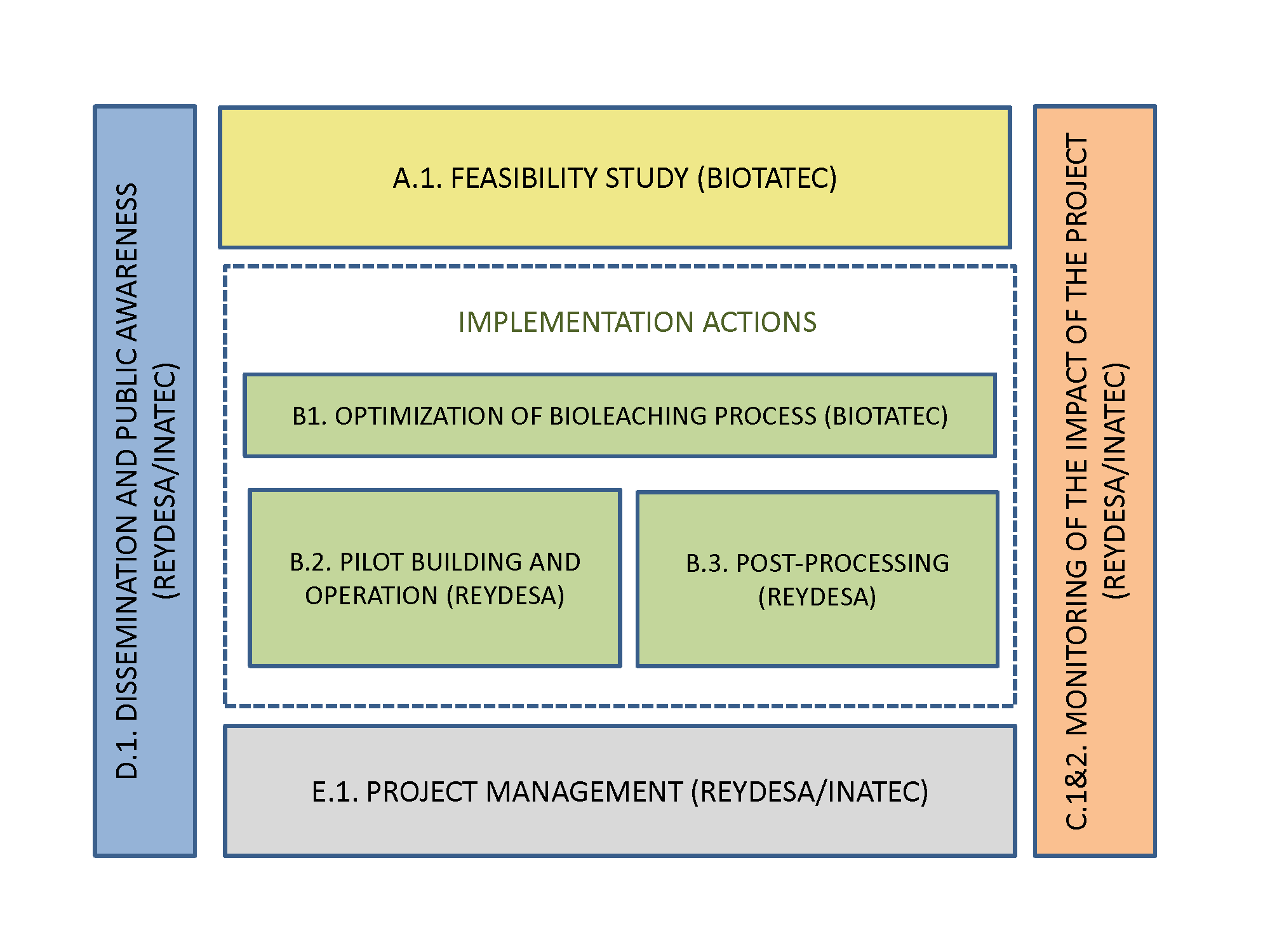

Main activities

A1: Feasibility study

B1: Optimisation of bioleaching process

B2: Pilot building and operation

B3: Post-processing

C1: Monitoring of the environmental impact

C2: Monitoring of the socio-economic impact

D1: Dissemination and public awareness

E1: Project management

Background information

Collection, treatment and recycling of WEEE is essential to improve the environmental management, contribute to a circular economy and enhance resource efficiency. In this way, the recycling of WEEE offers substantial opportunities in terms of making secondary raw materials available on the market. Many materials used by the EU industry come from secondary or recycled sources. Producing goods using recycled materials is often much less energy intensive than manufacturing goods from virgin materials. Recycling can thus reduce production costs and carbon emissions. Even though it cannot meet the EU industry's entire demand for raw materials, recycling has a great potential to improve Europe's resource efficiency. Using lower quantities of materials in product design can also play a part in improving access to raw materials in Europe.

WEEE is a complex mixture of materials containing precious and special metals as well as potentially toxic substances like lead, mercury, cadmium and beryllium, that poses considerable environmental and health risks if treated inadequately. Moreover, the production of modern electronics requires the use of scarce and expensive resources, for example, less than 1 % of total gold worldwide is obtained from European natural resources around 10 % is used for EEE production.

According to the European Commission, WEEE is one the fastest growing waste streams in the EU (3-5 % per year), with some 9 million tonnes generated in 2005, and expected to grow to more than 12 million tonnes by 2020 (http://ec.europa.eu/environment/waste/weee/index_en.htm). The vast amount of WEEE is rapidly growing worldwide due to growth in the electronics sector and use of technology in general. According to Namias (2013), EU produce approximately 20 Kg of ewaste/person/year, while USA produce about 7 Kg of e-waste/person/year. This discrepancy may be attributed to the varying definitions of e-waste; in the USA electronic waste generally consists of information technology and telecommunications equipment, monitors and televisions, whereas in Europe it also includes large household appliances, cooling and freezing appliances, and medical devices.

PCB are the main support used for the interconnection of electronic components in WEEE, containing around 30-50 % of metals, some of which are of high value although in small proportions, and their recovery constitutes a potential source of secondary raw materials. The conductive tracks of the PCB are in their entirety Cu, whereas, in certain contacts, the use of Au and Ag coatings on Cu is usually used. Moreover, the European Commission has also created a list of Critical Raw Materials (CRM) that can be found at https://ec.europa.eu/growth/sectors/raw-materials/specificinterest/critical_en. CRM combine a high economic importance to the EU with a high risk associated with their supply, being Pt the most important one that could be recovered from the PCB of WEEE. Until now, mechanical, pyrometallurgical and hydrometallurgical procedures have been used to recover the metals contained in the PCB. In order to obtain pure metals from these materials it is essential to combine different processes and it should be noted that in the treatment schemes currently applied in developed countries, the initial stage of treatment is usually a pyrometallurgical process focused on the recovery of the majority metal (usually Cu). Nevertheless, hydrometallurgical processes are usually not cost-effective and the organic parts of PCB of WEEE are not recovered.

An innovative 2-step technology, validated in ores as natural sources, is proposed to recycle the non-metallic fraction of PCB of WEEE in order to (i) produce methane during the anaerobic phase and (ii) recover metals as secondary raw materials (mainly Cu, Ag and Au) during the aerobic phase.

Milestones

Expected results

The main result of the project will be the demonstration of a 2-step bioleaching technology in the recovery process of valuable metals from the non-metallic fractions of PCB of WEEE currently incinerated, that will also allow to produce methane through the application of an anaerobic process to the organic fractions.

As a result of LIFE BIOTAWEE project, the total amount of metal recovered will increase up to 75-100 %, and up to 400 % in the recovery of gold, the most valued metal. In this sense, it is expected a reduction in hazardous waste generation of 0,3 Tn at the end of the project, 0,9 Tn 3 years after the end and 6,5 Tn as final goal.

This new recovery process aims to be cost-effective and to reduce the final cost of recovery of metals up to 50% compared with hydrometallurgical processes and 35-40 % compared with 1-step bioleaching process.

REYDESA manages PCBs from WEEEs and now the 100 % of them are sent to recovery through pirometalurgy. LIFE BIOTAWEE proposes a technical solution for a technologically, economically and environmentally viable process to enable the increasing management of tons of PCBs.

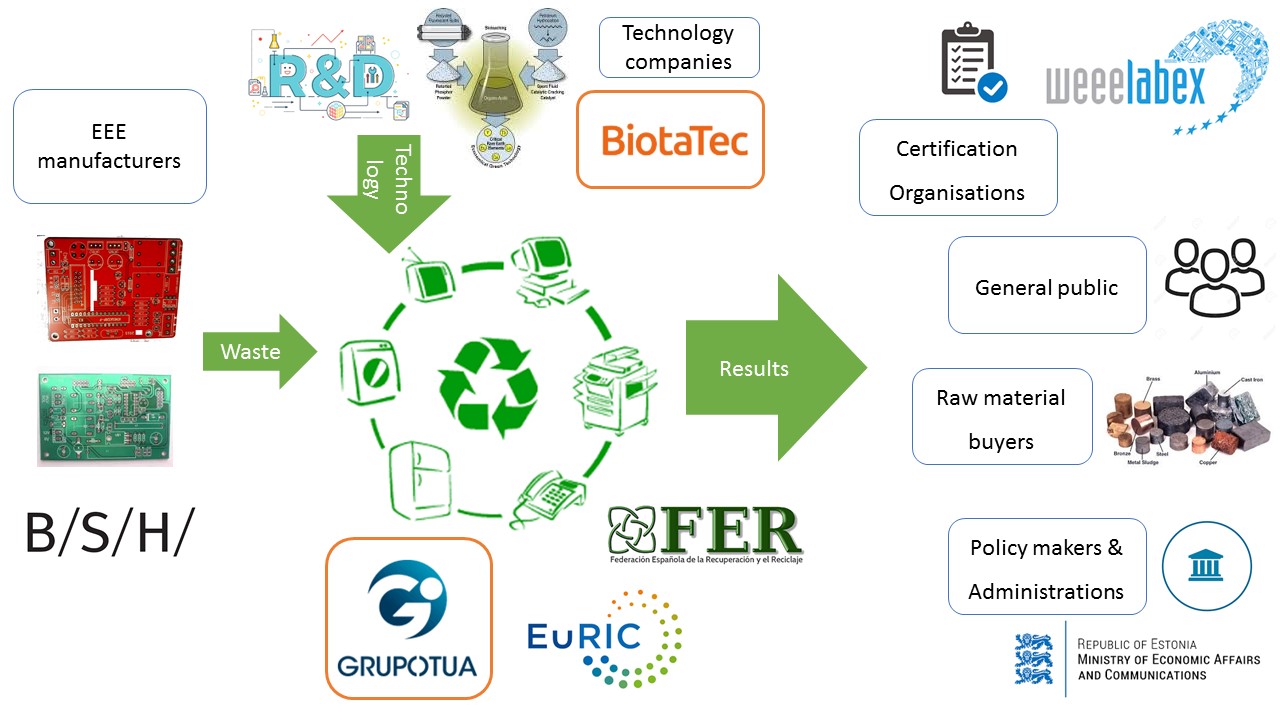

Stakeholders and target groups

The main aim of the project is to recover valuable metals (mainly Cu, Ag and Au) from the non-metallic fraction of PCB of different WEEE by the application of a novel and innovative more efficient 2-step bioleaching technology combining aerobic and anaerobic treatment. This involves the technical, economic and environmental feasibility assessment of recycling the WEEE to produce a new more sustainable recovery process and obtain metallic raw material for other processes, at industrial scale.

To achieve this goal, it is important to count with relevant stakeholders to cover the different profiles affected by the project. In this sense, by one side, the project consortium is formed by a technology provider (BIOTATEC), who will implement and validate the innovative technology, and by an industrial company in the sector of the recovery (REYDESA), who is the expert in the treatment and recovery of different kind of residues, including the WEEE. In addition, REYDESA, has the support of INATEC (as an affiliated entity), where is located the R&D Department of OTUA Group.

LIFE BIOTAWEE importance is not only limited to the direct partners, and also aims to improve the environmental performance of all agents involved in the life cycle of WEEE, such as producers, distributors and consumers, and in particular those directly involved in the collection and treatment of WEEE. In this context, the project will try to involve at least one representative of the main sectors involved in the recovery of WEEE or potentially affected by the project's results:

Project participants

REYDESA RECYCLING is a leader company in the recovery of ferrous and non-ferrous metals. They offer a versatile service to manage a wide range of metallic waste, being specialized in the recovery of copper. Their infrastructure allows them to treat all types of waste of diverse composition and origin. In 50,000 m2 of facilities they have technologically advanced productive means that allow to manage a wide range of complex waste effectively. At the same time, they treat and decontaminate WEEE and VFU. With the aim of offering great versatility when it comes to recycling complex solid waste, they have multiple and complementary treatment facilities. In the project, REYDESA, has the support of INATEC (as an affiliated entity). In INATEC is located the R&D Department of OTUA Group in which both REYDESA and INATEC are included. OTUA Group has more than 40 years of experience and is one of the leading companies in the recycling of metals in Europe. It is an industrial group formed by 10 companies dedicated to Recycling, Distribution and Research with industrial facilities exceeding 200,000 m2.

BIOTATEC was created in 2007 as a spin-off from Tallinn University of Technology. For 9 years, the company performed metagenomic testing of environmental samples as ISO17025 accredited testing lab and fulfilled various R&D projects for industries and governmental institutions. Since 2010 the company has investigated the possibilities to improve the technology of bioleaching for polymetallic ores that contain organo-metallic complexes. In 2015 given R&D became the main activity of the SME. Company has submitted 2 patent applications related to innovative bioleaching technology with higher efficiency for ores considered to be “low-grade” for conventional metallurgy and even conventional bioleaching.

© Copyright 2019 - Designed by COASER IT