B2.3. Pilot set-up and operation (3)

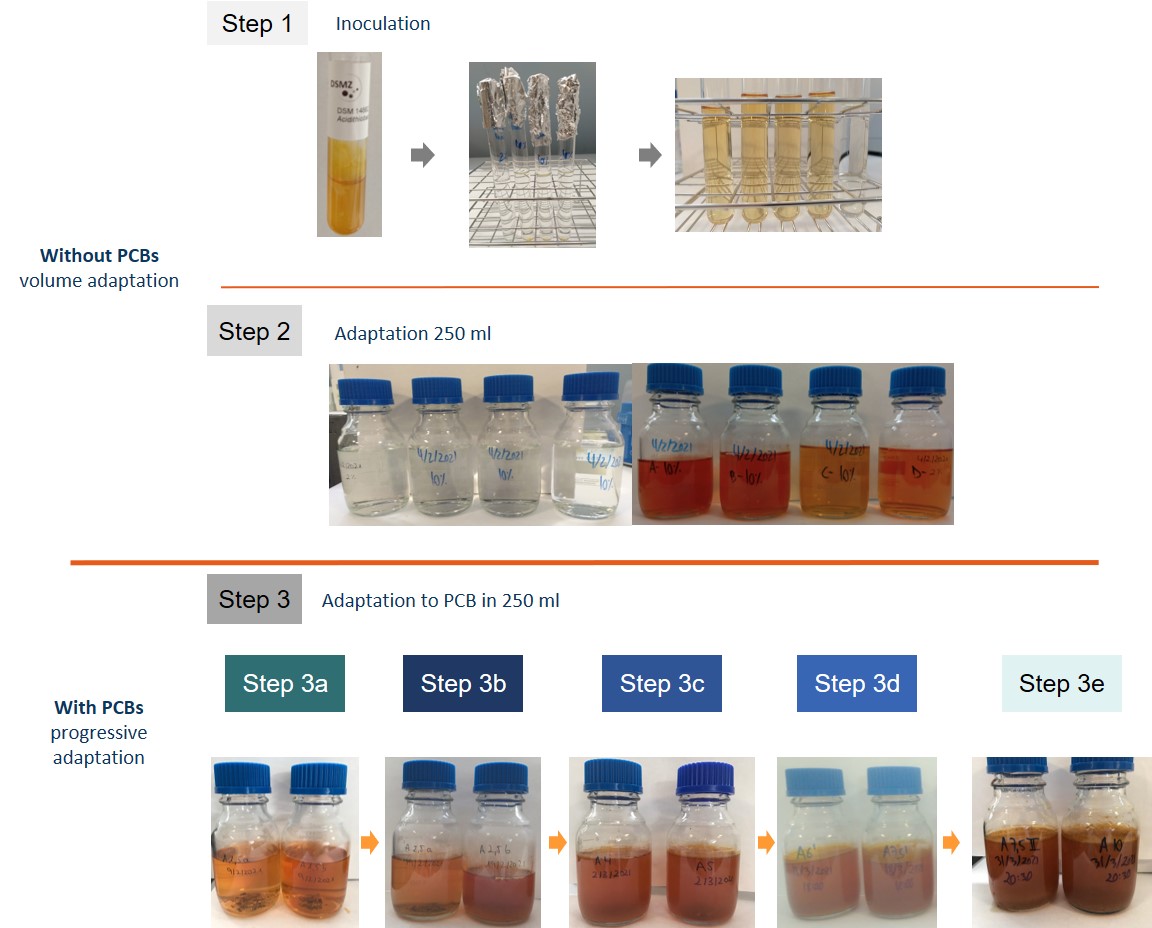

The adaptation of microorganisms has been carried out at 10g/L of the non-metallic fraction of PCB to the microorganisms Acidithiobacillus ferroxidans, in the 882 medium.

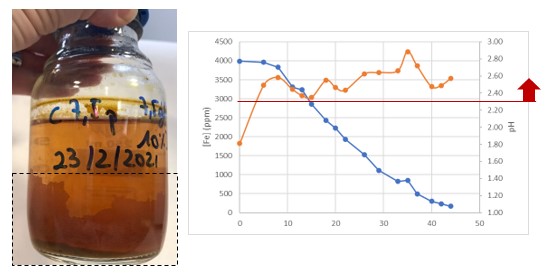

A precipitate formation has been observed on the walls of the flasks, showing the formation of jarosite, a compound made up of iron, when the pH is greater than 2.3. By precipitating iron, the concentration of iron in the medium, necessary for the metabolism of microorganisms, is reduced and, therefore, their yield for the bioleaching of metals is reduced.

After the tests carried out, it is concluded that the pH control at 2 produces an improvement in performance, by avoiding the precipitation of iron, and that it is not necessary to add a greater amount of iron to the medium, since no notable influence has been detected on the result of the tests carried out.

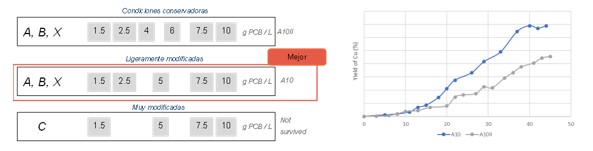

Different adaptation steps have been tested, with greater and lesser number of steps, and the results show that the intermediate conditions are the most optimal for the adaptation of these microorganisms to this type of waste.

With these optimal conditions, the microorganisms have been adapted to 10 g/L of non-metallic fraction of PCB, and they have been adapted with this S/L ratio to a higher volume, until reaching the 50L necessary for the tests in the pilot equipment.

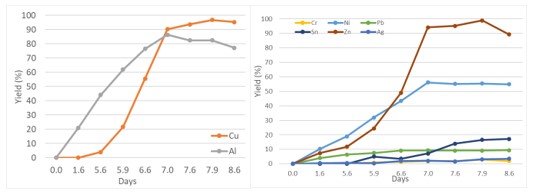

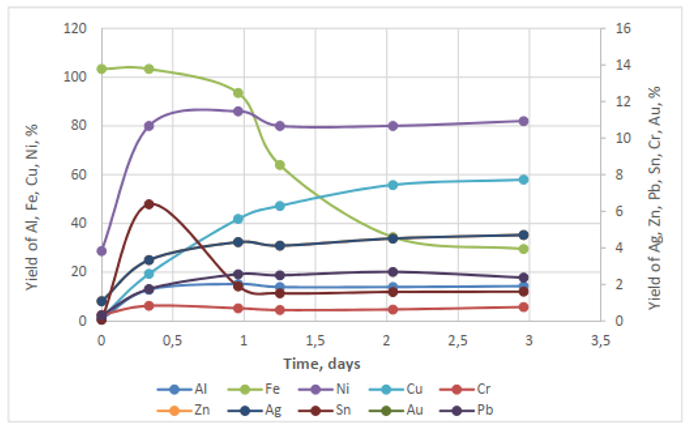

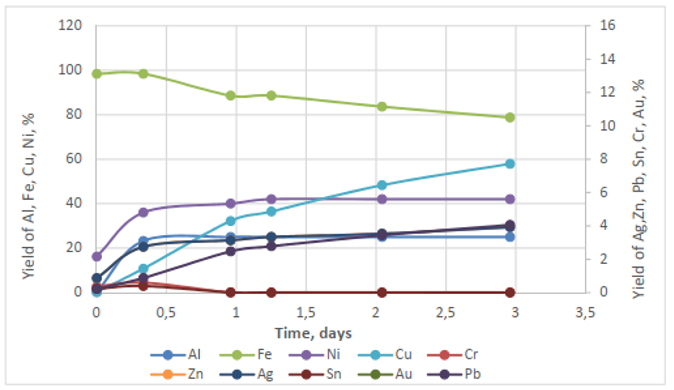

Tests on 50 L in the pilot plant have been carried out, in which temperature control has been maintained at 30 ºC, pH constant at 2, and regular measurements of the metal content in the liquid have been made, by taking samples and analyzing them at the ICP-OES. The metals that have been monitored are Al, Cr, Fe, Ni, Cu, Zn, Ag, Sn, Au and Pb.

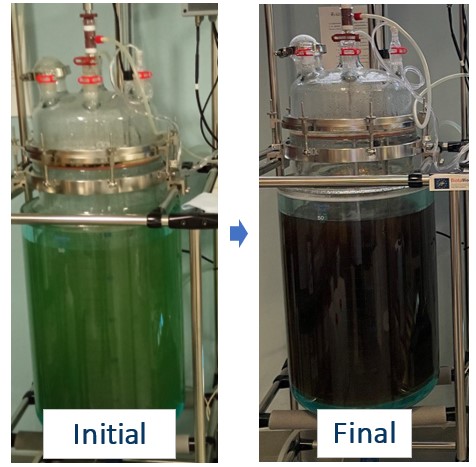

A colour change has been observed in the middle, between the beginning and the end of each experiment, which can be seen in the figure.

Three experiments have been carried out in 50L, and the main conclusions drawn are the following:

- Analyzing the results of the metals present in an amount greater than 6% in the residue, an average copper extraction of 90% is obtained, which in some cases even exceeds 94%. In the case of Aluminum, the efficiency reaches values of 80%.

- In the case of metals with less presence in the waste (<1%), Nickel and Zinc show extraction values of 56 and 84% respectively, so it is estimated that these microorganisms could be used to extract these metals from other residues that contain them in higher concentration.

- Gold leaching from the residue is not detected, and silver extraction is less than 4% in all cases. It is concluded that other types of microorganisms are necessary to extract these metals, but, in addition, their low concentration in the residue makes their recovery difficult with this method.

Figure. Results obtained in one of the experiments.

B3.2. Cost-effectiveness analysis, project continuation and replication (1)

Based on knowledge developed during implementation of previous tasks, the transferability of this technology for the application to other residues is being evaluated. In particular, dust recovered from the aspiration system in the mechanical treatment of WEEE has been selected for experimental tests with bioleaching, because this dust is a residue with high content in Cu and other metals but with limited treatment options due to its granulometry and characteristics.

In particular, the tests defined are:

- 2 step bioleaching (anaerobic and aerobic step) applied to dust recovered from the mechanical treatment of PCB.

- Evaluation of the aerobic step in dust recovered in the mechanical treatment of WEEE, with higher Cu content.

B3.1. Metal extraction from pregnant solutions

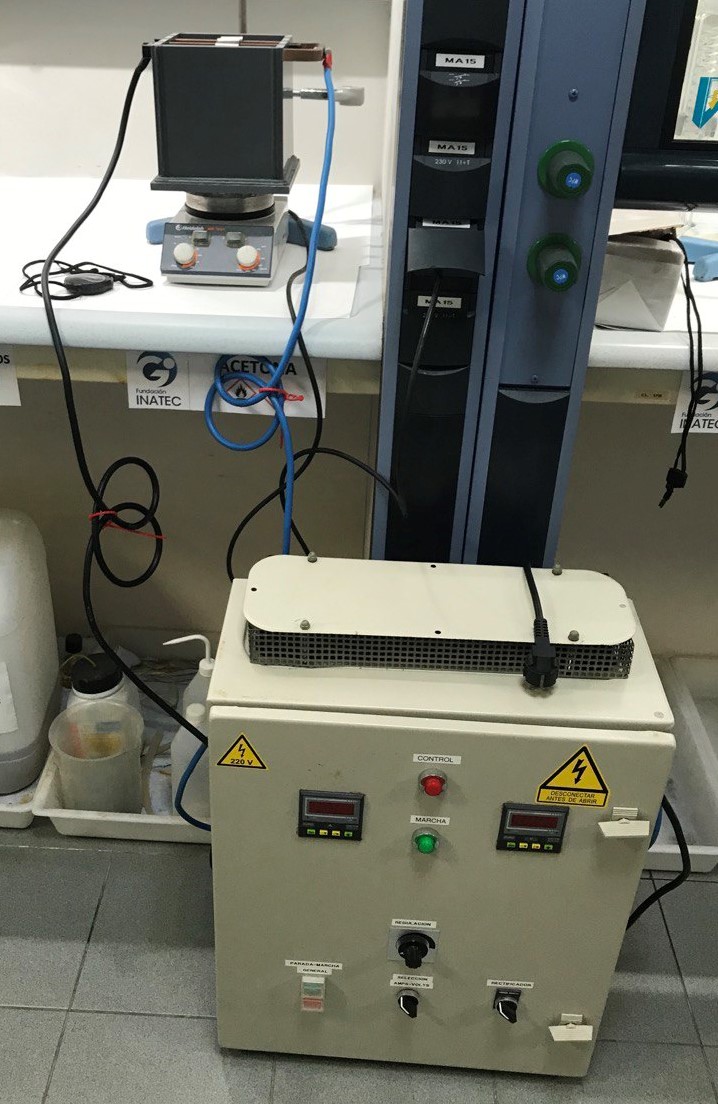

An in-depth literature review of metallurgical processes to recover the strategic metals present in pregnant solution obtained in bioleaching has been performed. Among several methods, the most relevant ones were selected to be tested: electrowinning, precipitation, and cementation.

- Cementation: is a type of precipitation in which ions are reduced to zero valence at a solid metallic interface.

- Precipitation: a sequential procedure was designed to precipitate metals separately. The resulting precipitate is filtered, washed and calcined. Further evaluation of the resulting solid is performed.

- Electrowinning: an electrical current is passed from an inert anode (oxidation) through a leach solution containing the dissolved metal ions so that the metal is recovered as it is deposited in an electroplating process onto the cathode (reduction).

Fig. Electrowinning equipment used in the tests

Fig. Electrowinning equipment used in the tests

B2.3 Pilot set-up and Operation (2)

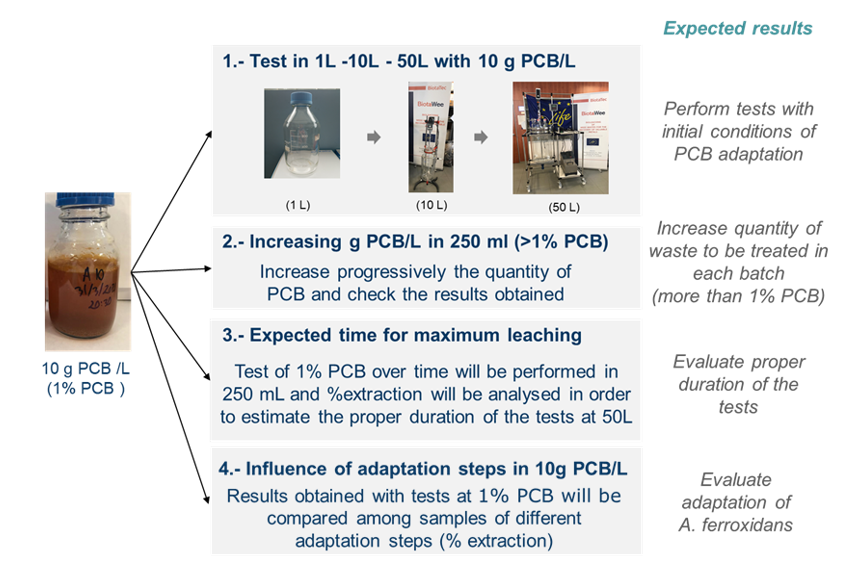

After the adaptation process, experiments have been defined in order to increase knowledge of the optimized parameters for the tests in aerobic conditions:

- Directly perform progressive increase of volume in the tests, reaching 50L.

- Increasing concentration of rejected fraction of PCB from 1% to 10% in 250 mL (ongoing).

- Expected time for maximum leaching.

- Influence of adaptation steps in 10g PCB/L.

Figure. Tests performed in aerobic conditions and expected results

Figure. Tests performed in aerobic conditions and expected results

It has been demonstrated in these tests that the precipitation of jarosite is avoided when controlling the pH, minimizing the losses of iron in the dissolution, increasing the performance and also reducing the time for the tests. Tests with improved conditions have been started, as can be observed in the figure.

Fig. Evolution of the tests in the 50 L reactor.

Fig. Evolution of the tests in the 50 L reactor.

The results obtained are still being evaluated, and these experiments will be repeated, in order to extract robust outcomes from the tests.

B2.3. Set-up and Operation

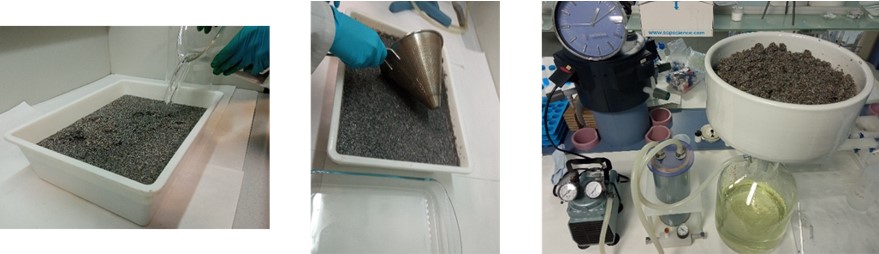

Before the adaptation of the microorganisms, a series of processes to adapt the laboratory media to the work procedures in bioleaching were carried out:

- The development of a safety and health protocol has been developed

- Sterilization techniques for the media have been studied

- Study of the microorganisms that could be present in the reaction conditions that can compete with the Acidithiobacillus ferroxidans.

- Non-metallic part of PCB pre-treated with saturated NaCl and further washed

- Test equipment performance during scaling up (250 ml - 1 L - 10 L - 50 L)

Non-metallic part of PCB pre-treated with saturated NaCl and further washed

Adaptation and scaling up process of Acidithiobacillus ferroxidans with the non-metallic fraction obtained after mechanical treatment of PCBs:

The process consists in 6 steps:

- Step 1: Vials inoculation

- Step 2: Adaptation to 250 ml

- Step 3: Adaptation to PCB in 250 ml

- Step 4: Adaptation to PCB in 1 L

- Step 5: Adaptation to PCB in 10 L

- Step 6: Adaptation to PCB in 50 L

Steps 1-3 from adaptation and scaling up process.

Steps 4-6 from adaptation and scaling up process.

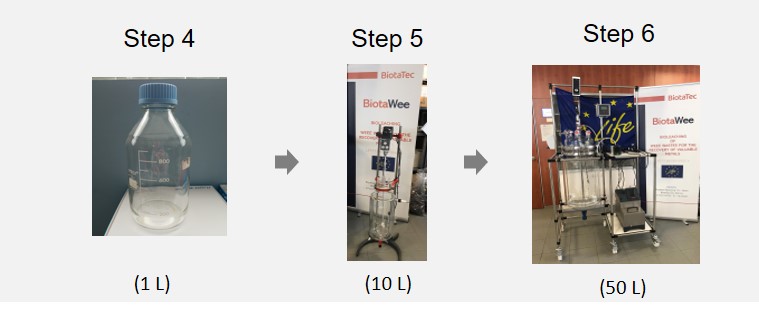

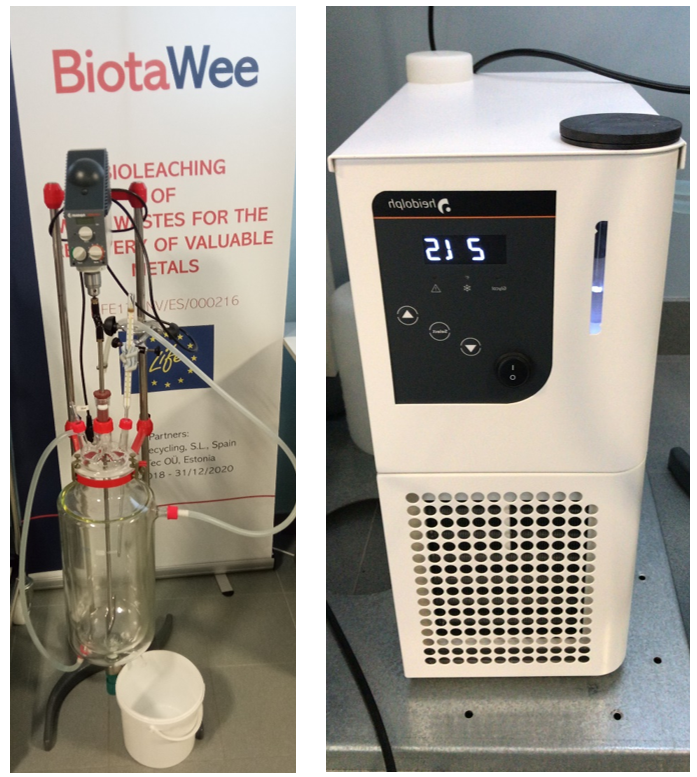

B2.2. Pilot building and installation (3)

After tests with the 10L-reactor already owned by INATEC, equipped with sensors and agitation, it was concluded that a new reactor and chiller should be purchased, in order to improve the temperature control in this volume.

Figure. 10 L reactor and chiller for the adaptation process

Figure. 10 L reactor and chiller for the adaptation process

Additionally, in order to avoid blockages with the PCB, a specific system to open the reactor has been also included in the design.

Figure. Specific discharge nozzle to avoid blockages in the 10 L reactor

Figure. Specific discharge nozzle to avoid blockages in the 10 L reactor

B2.2. Pilot building and installation.

The development of a 50 L prototype for bioleaching operations of the non-metallic fraction of PCBs after mechanical treatment by the microorganisms Acidithiobacillus ferroxidans was carried out.

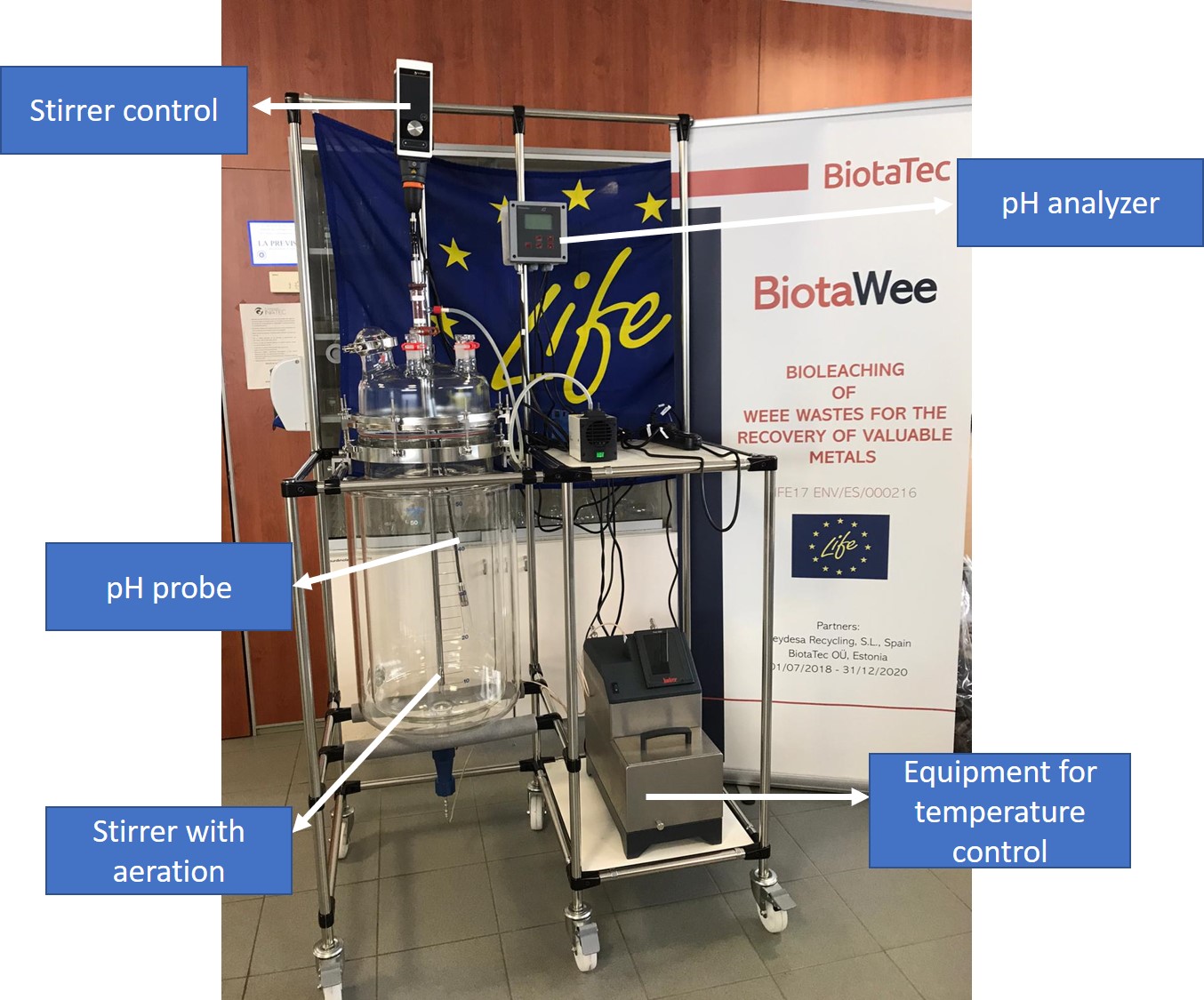

50 L prototype built for BIOTAWEE Project.

The prototype consists on the following equipment to control the operating conditions during bioleaching:

- pH analyzer that will facilitate both the supervision of the evolution of the pH of the reaction and also the possibility to the pH at a constant value.

- Stirring controller + aerated rod for controlled agitation that does not hinder the evolution of microorganisms and also incorporates aeration in the rod to improve air recirculation for the benefit of the aerobic reactions that take place.

- T controller that allows us a precise control which is of great importance for the reactions and survival of microorganisms.

B2.2. Pilot building and installation.

The design of the required technology to reproduce the process has been carried out, increasing the scale to a capacity of 50L. Providers have been contacted and the revision of bids is nearly completed.

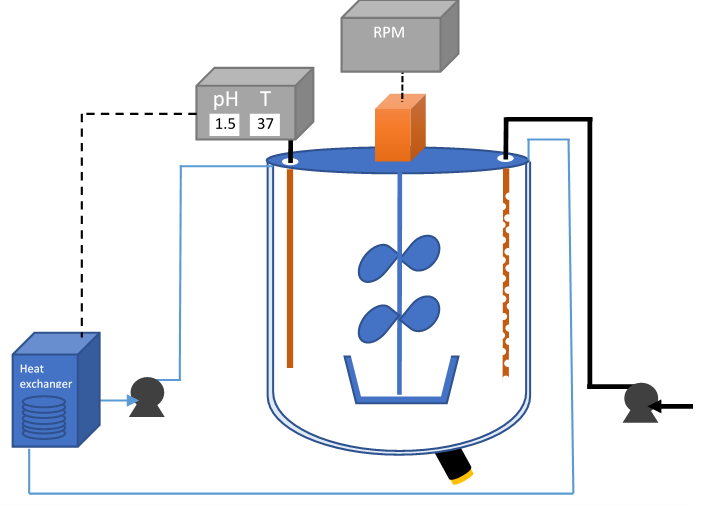

Design of the required technology for the 50 L reactor.

In the meantime, the revision of the laboratory material needed for the test has been performed. Before starting the test on a 50L reactor, the consortium has to be previously adapted to the PCB in flasks of 250ml, increasing the volume progressively, being the previous volume to the 50L-reactor a 10L-reactor already owned by INATEC. This reactor, equipped with sensors and agitation, has been checked and the reagents and material required for working with microorganisms have been listed.

Test performed in the 10 L reactor in order to check the performance.

B2.1. Supply/sample preparation.

Processing PCBs includes several steps of crushing and separation until a non-metallic fraction to test by bioleaching technology is obtained. Next figure shows the three steps of the global process where the material has to pass until the final fraction is achieved:

Material through each step of the process.

1st STEP: The process begins with the crushing of the material in a shredder.

2nd STEP: The material is introduced in the mill during continuous cycles.

3rd STEP: The aim of this step is to separate the metallic fraction from the non-metallic one.

MATERIAL FOR BIOLEACHING: The non-metallic fraction obtained in the previous step is the one selected to be used in the bioleaching process that will be carried out by BIOTAWEE consortium.

B1.3. Bench scale tests (20l) combining 2-step bioleaching process

The bench-scale reactors are equipped with all necessary sensors, sampling ports, stirrers and control module for testing the process in larger scale.

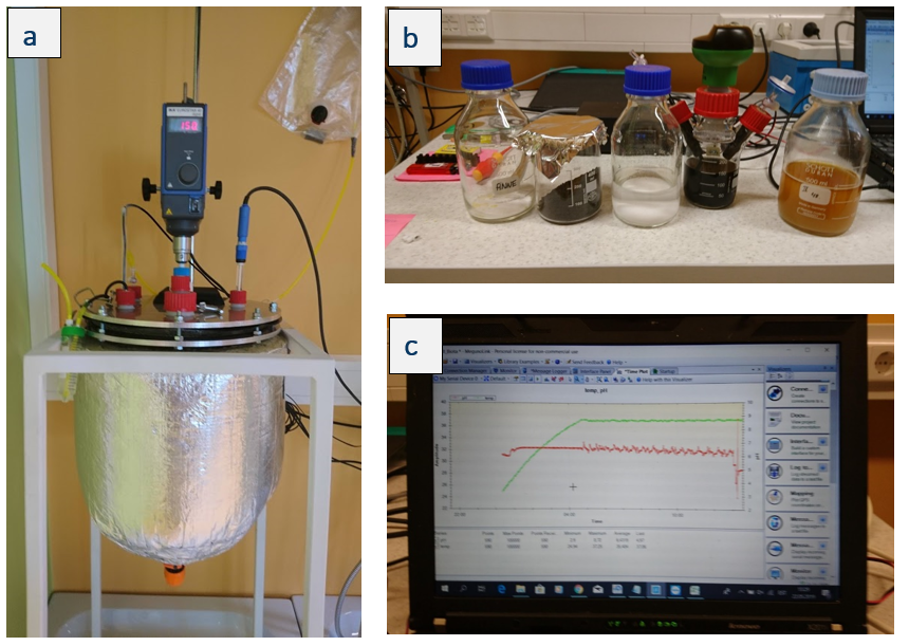

Figure. a. The 20 L glass reactor with sensors, stirrer, sampling ports and control unit; b. The components of culture media, the raw material to be treated and the inoculum ARGCON5 prepared for a bench scale experiment; c. Computer interface of the control module.

The basic information from the 20-liter experiment is similar to that obtained from lab scale, however:

- The extraction of Cu using the 2-step anaerobic-aerobic process was almost twice more efficient than using the aerobic process only (28,02% vs 13,58% Cu yield).

- Moderate extraction of Pt (efficiency 5.6%) was observed in the anaerobic step,

- Au and Ag were not released in aerobic neither in the 2-step combined anaerobic-aerobic process.

- As the main value of the anaerobic step is generation of biogas, attention should be paid to the proper choice of inoculum viability and concentration.

pH is an important parameter to follow the kinetics of the bioleaching process and a reliable indicator on the possibility of methane generation.

B1.2. Experiments performed in the aerobic step

Aerobic cultivation experiments with pure culture Acidithiobacillus ferrooxidans DSM14882 were performed with the residue of PCBs of WEEE suspension from the anaerobic phase in 250- mL shake flasks. The cultures were aerated in a shaker simulating the aerobic phase of bioleaching process.

Figure. Bioleaching aerobic phase. Release of metals in PCB suspensions with acidophilic pure culture Acidithiobacillus ferroxidans

Figure. Bioleaching aerobic phase. Release of metals in PCB suspensions (untreated material) with acidophilic pure culture Acidithiobacillus ferroxidans.

A release of 100% Fe, 80% Ni, and 60% Cu from the residue of PCBs of WEEE originating from the anaerobic phase was obtained within 48 hours. The metal leaching efficiency is almost the same as with untreated PCBs of WEEE, except for Ni.

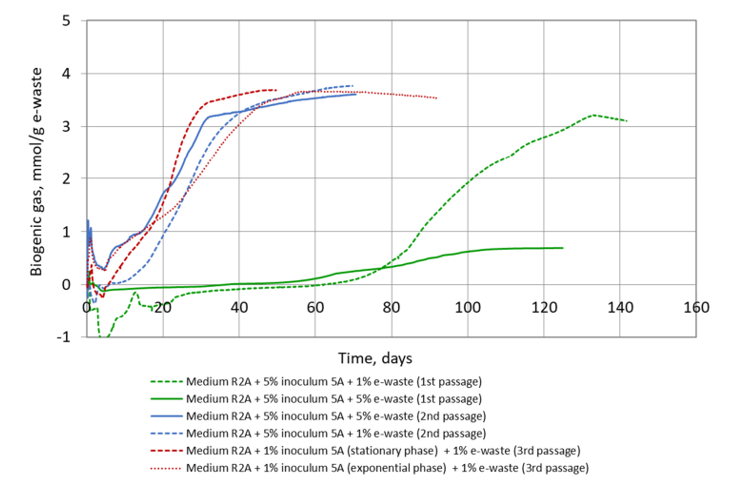

B1.1. Experiments performed in the anaerobic step

Experiments have been performed to compare metal leaching in the following conditions:

- with inoculum ARGCON5 (inoculum 5A) vs inoculum 32 (e-waste-adapted microbial community);

- with medium (plus inoculum) vs e-waste suspension (plus inoculum);

- with e-waste suspension (plus inoculum) vs e-waste suspension (without inoculum);

- with culture media (R2A broth or vinasse) vs sterilized tap water;

- compare different media components - betaine vs vinasse

Figure. Changes in biogenic gas yield in microcosms with suspensions of PCBs of WEEE samples, T = 37ºC, inoculum ARGCON5 (inoculum 5A), 1% and 5% substrate, normalized to inoculum.

It was obtained that with several passages to the fresh media (adaptive laboratory evolution) the biogas production as well as metal leaching ability of consortia was improved.

A1.4. Analysis of metals content, number of microorganisms and pH

Culture media with suspension of PCBs in reactor flasks were sampled for liquid phase to determine the metal content by ICP-MS method. The initial yields of metals were moderate as the consortium had not yet been adapted to the material (substrate). On the same days, samples were taken from cultivation media for enumeration and identification of microorganisms. Samples were centrifuged (5000 rpm, 10 min) to separate the biomass of microorganisms, from which in turn the DNA was isolated.

The enrichment of microbial consortium from e-waste was successful as the number of microorganisms at the end of the experiment was comparatively high (107 CFU/ml,). The pH of the cultivation medium was in the range facilitating the growth of methanogens; however, several metals are in the form insoluble compounds at this pH (pH 8.5), being the majority of metals leached only in the second, acidophilic phase.

In the current activity the applicability of consortium ARGCON5 for the use with PCBs of WEEE was proved. It was possible to enrich a methane producing microbial community from e-waste. Although the initial methane yield and metals extraction ability were modest, they can be improved in further steps with modifying the medium and by means of adaptive laboratory evolution (Action B1).

A1.3. Principal scheme for microbiological treatment of PCBs of WEEE.

Photo by A. Menert.

Photo by S. Kuuse.

Photo by S. Kuuse

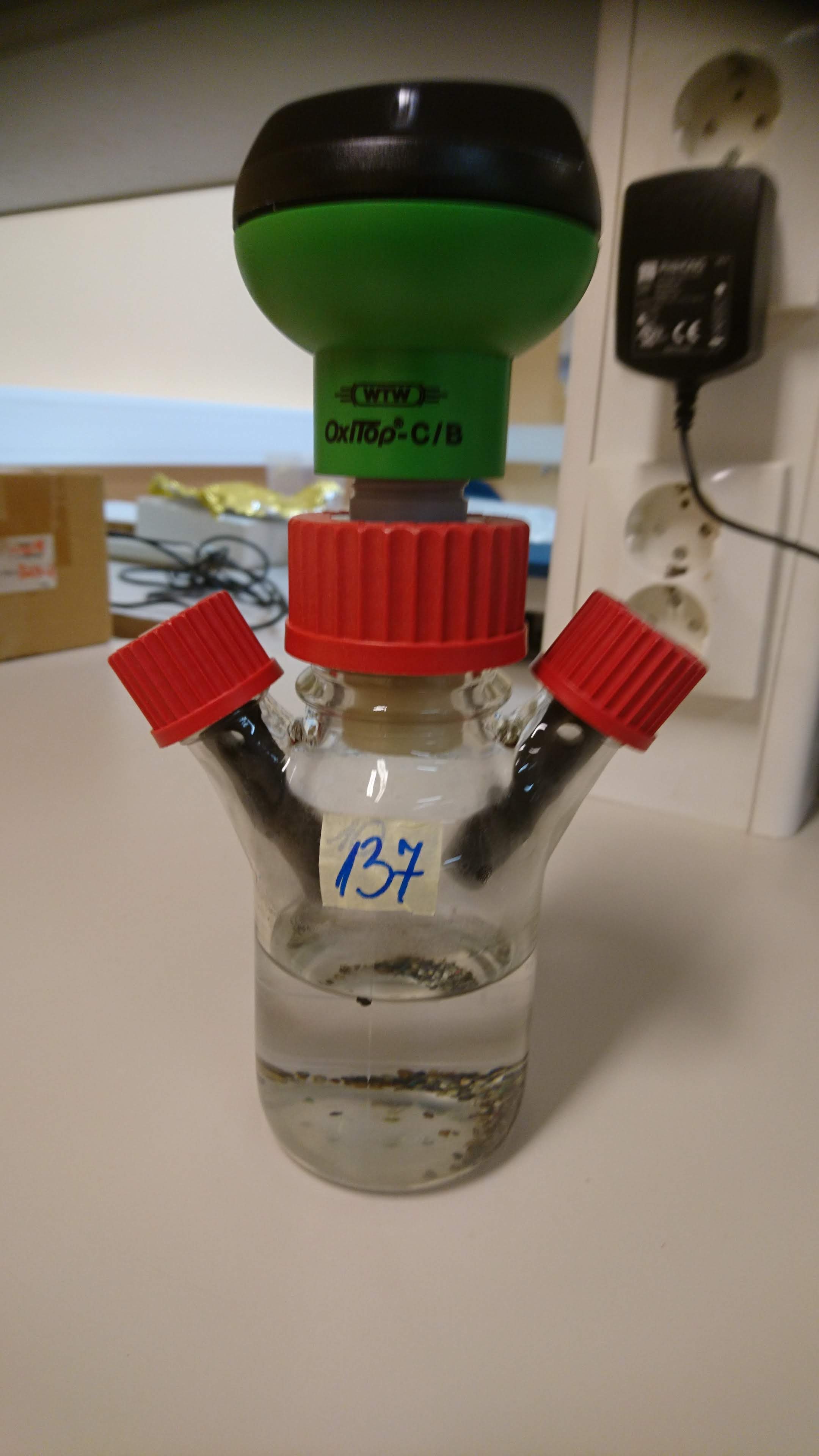

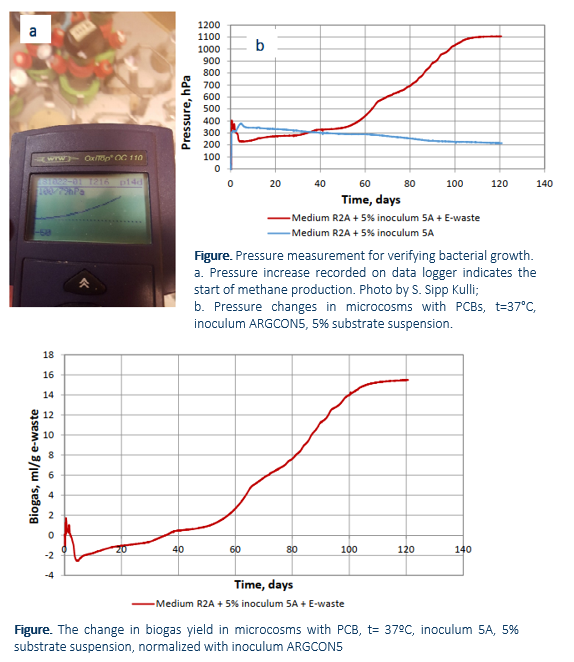

A1.2. Study of microbial biodegradation potential of indigenous species of ARGCON5 with bioleaching cultivation experiments in microcosms with OxiTop AN measuring system.

The flasks of OxiTop AN measuring system with PCBs of WEEE in growth medium inoculated with ARGCON5 and with growth medium and inoculum, 100th day of experiment. The flask with PCBs of WEEE is remarkably darker.

Photo by A. Menert.

The flasks of OxiTop AN measuring system with PCBs of WEEE in growth medium inoculated with ARGCON5 adapted to e-waste, with growth medium and inoculum only and with PCBs of WEEE in growth medium (without inoculum), 10th day of experiment. In the flask with all components added, gas bubbles indicate degradation of organic matter.

Photo by A. Menert.

A1.1. Preparation of inoculum for the bioleaching cultivation experiments.

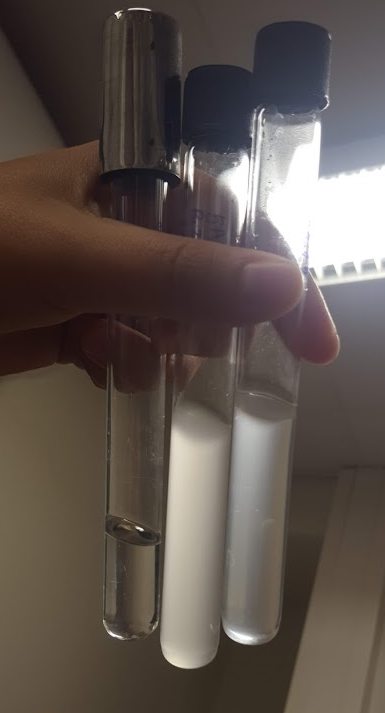

Before placing into the bioleaching experiment, the Inoculum CELMS No EEUT ARGCON5 is pre-cultivated in test tubes in a thermostated shaker at t=37°C.

Photo by S. Sipp Kulli.

After pre-cultivation the remarkable haze in test tubes with inoculum demonstrates the growth of bacteria.

Photo by S. Sipp Kulli.

The BiotaTec coworkers of Kärt Ukkivi, MSc and Anne Menert, PhD are examining the quality of inoculum CELMS No EEUT ARGCON5. The Inoculum has grown up and is ready to be added to the non-metallic fraction of PCBs of WEEE.

Photo by S. Sipp Kulli.

© Copyright 2019 - Designed by COASER IT