B3.2. Cost-effectiveness analysis, project continuation and replication (1)

Based on knowledge developed during implementation of previous tasks, the transferability of this technology for the application to other residues is being evaluated. In particular, dust recovered from the aspiration system in the mechanical treatment of WEEE has been selected for experimental tests with bioleaching, because this dust is a residue with high content in Cu and other metals but with limited treatment options due to its granulometry and characteristics.

In particular, the tests defined are:

- 2 step bioleaching (anaerobic and aerobic step) applied to dust recovered from the mechanical treatment of PCB.

- Evaluation of the aerobic step in dust recovered in the mechanical treatment of WEEE, with higher Cu content.

B3.1. Metal extraction from pregnant solutions

An in-depth literature review of metallurgical processes to recover the strategic metals present in pregnant solution obtained in bioleaching has been performed. Among several methods, the most relevant ones were selected to be tested: electrowinning, precipitation, and cementation.

- Cementation: is a type of precipitation in which ions are reduced to zero valence at a solid metallic interface.

- Precipitation: a sequential procedure was designed to precipitate metals separately. The resulting precipitate is filtered, washed and calcined. Further evaluation of the resulting solid is performed.

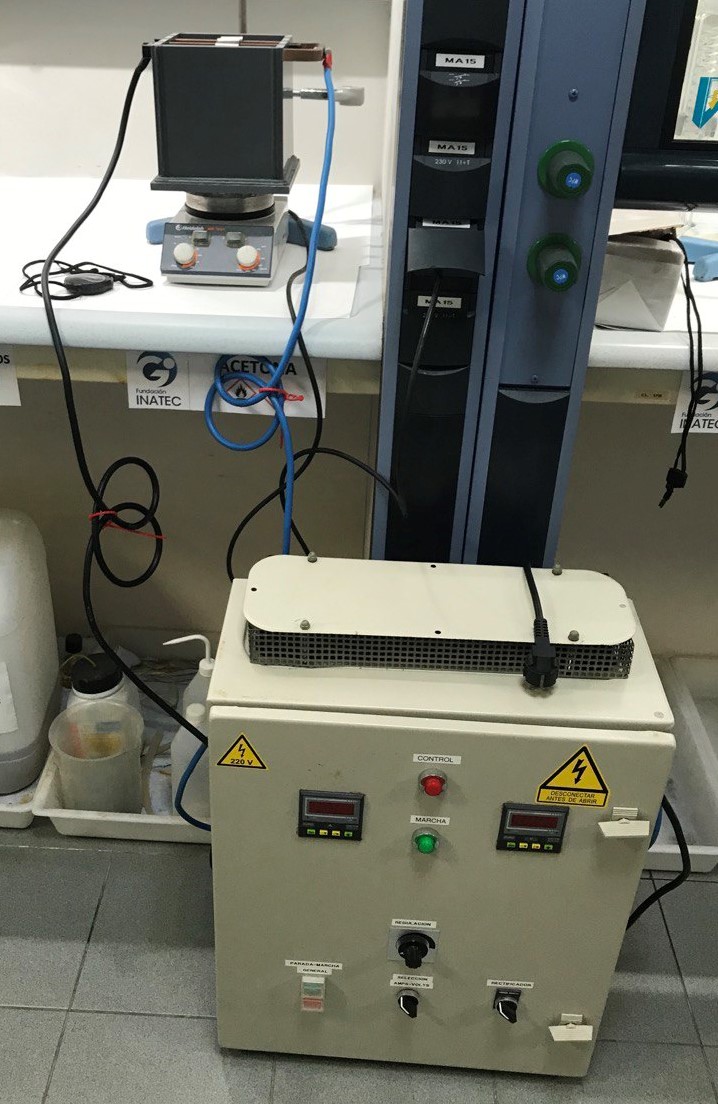

- Electrowinning: an electrical current is passed from an inert anode (oxidation) through a leach solution containing the dissolved metal ions so that the metal is recovered as it is deposited in an electroplating process onto the cathode (reduction).

Fig. Electrowinning equipment used in the tests

Fig. Electrowinning equipment used in the tests

© Copyright 2019 - Designed by COASER IT