B1. Optimization of specific parameters and microbial consortia (3)

B1.3. Bench scale tests (20l) combining 2-step bioleaching process

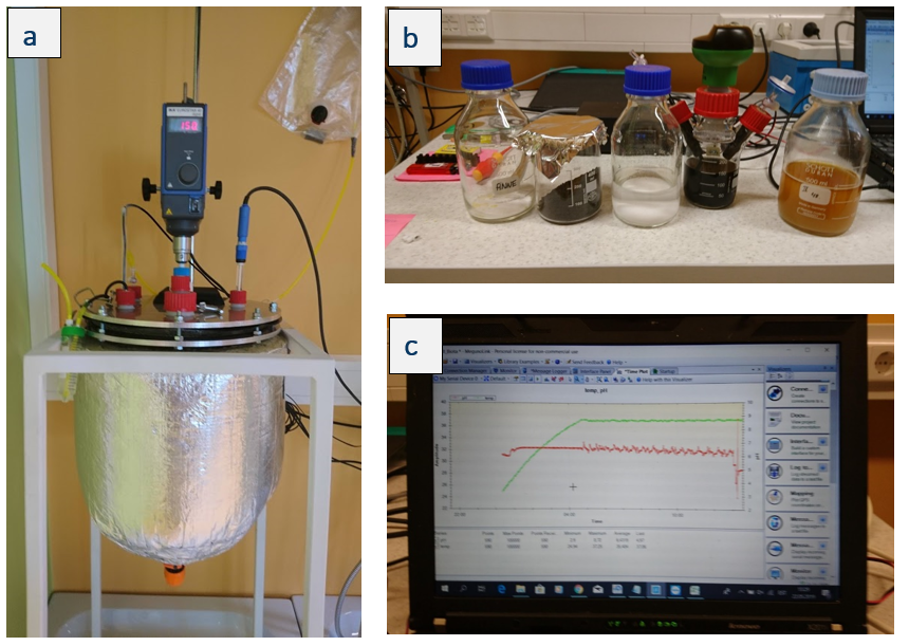

The bench-scale reactors are equipped with all necessary sensors, sampling ports, stirrers and control module for testing the process in larger scale.

Figure. a. The 20 L glass reactor with sensors, stirrer, sampling ports and control unit; b. The components of culture media, the raw material to be treated and the inoculum ARGCON5 prepared for a bench scale experiment; c. Computer interface of the control module.

The basic information from the 20-liter experiment is similar to that obtained from lab scale, however:

- The extraction of Cu using the 2-step anaerobic-aerobic process was almost twice more efficient than using the aerobic process only (28,02% vs 13,58% Cu yield).

- Moderate extraction of Pt (efficiency 5.6%) was observed in the anaerobic step,

- Au and Ag were not released in aerobic neither in the 2-step combined anaerobic-aerobic process.

- As the main value of the anaerobic step is generation of biogas, attention should be paid to the proper choice of inoculum viability and concentration.

pH is an important parameter to follow the kinetics of the bioleaching process and a reliable indicator on the possibility of methane generation.

B1.2. Experiments performed in the aerobic step

Aerobic cultivation experiments with pure culture Acidithiobacillus ferrooxidans DSM14882 were performed with the residue of PCBs of WEEE suspension from the anaerobic phase in 250- mL shake flasks. The cultures were aerated in a shaker simulating the aerobic phase of bioleaching process.

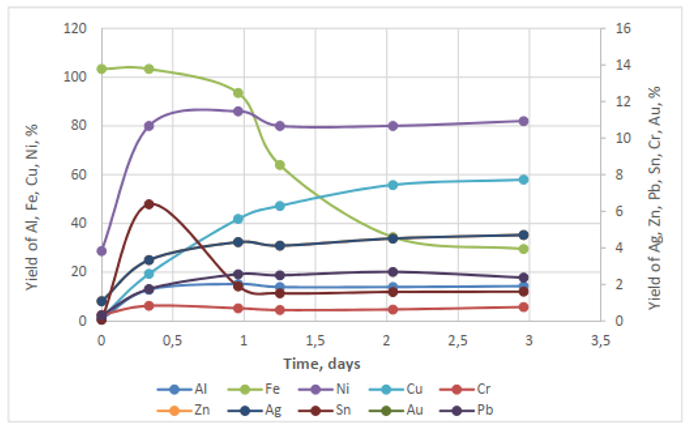

Figure. Bioleaching aerobic phase. Release of metals in PCB suspensions with acidophilic pure culture Acidithiobacillus ferroxidans

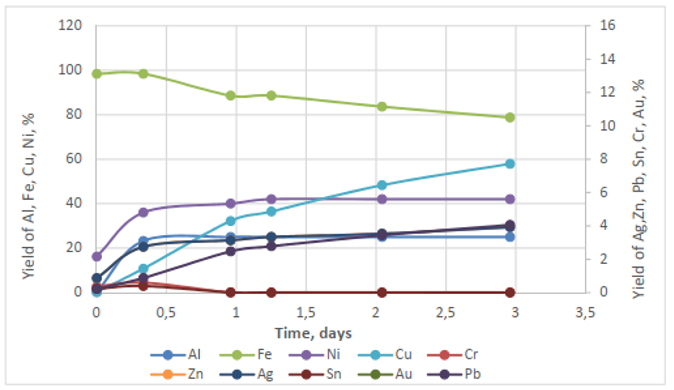

Figure. Bioleaching aerobic phase. Release of metals in PCB suspensions (untreated material) with acidophilic pure culture Acidithiobacillus ferroxidans.

A release of 100% Fe, 80% Ni, and 60% Cu from the residue of PCBs of WEEE originating from the anaerobic phase was obtained within 48 hours. The metal leaching efficiency is almost the same as with untreated PCBs of WEEE, except for Ni.

B1.1. Experiments performed in the anaerobic step

Experiments have been performed to compare metal leaching in the following conditions:

- with inoculum ARGCON5 (inoculum 5A) vs inoculum 32 (e-waste-adapted microbial community);

- with medium (plus inoculum) vs e-waste suspension (plus inoculum);

- with e-waste suspension (plus inoculum) vs e-waste suspension (without inoculum);

- with culture media (R2A broth or vinasse) vs sterilized tap water;

- compare different media components - betaine vs vinasse

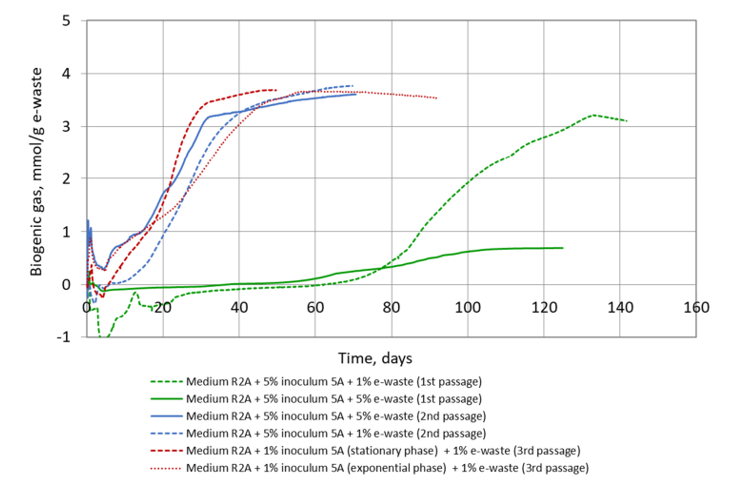

Figure. Changes in biogenic gas yield in microcosms with suspensions of PCBs of WEEE samples, T = 37ºC, inoculum ARGCON5 (inoculum 5A), 1% and 5% substrate, normalized to inoculum.

It was obtained that with several passages to the fresh media (adaptive laboratory evolution) the biogas production as well as metal leaching ability of consortia was improved.

© Copyright 2019 - Designed by COASER IT