Update on the progress

B2. Pilot building and operation.

Pilot building of the bioreactor will be carried out in REYDESA´s facilities in Spain and 10-20 semi-industrial batches will be developed.

B2.2. PILOT BUILDING AND INSTALLATION

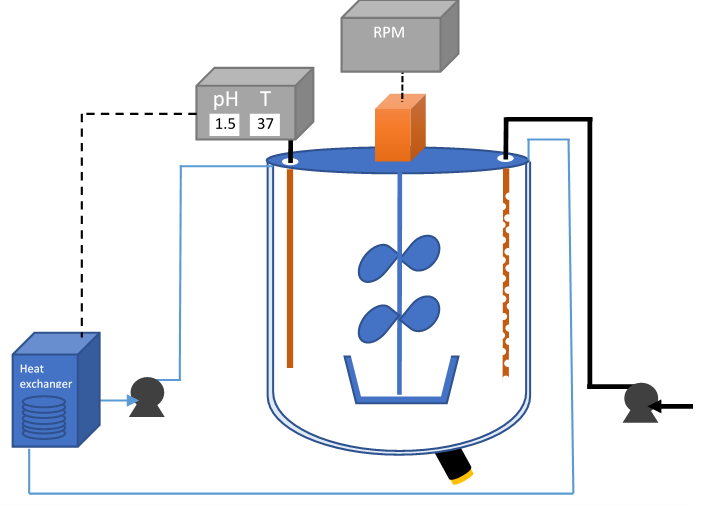

The design of the required technology to reproduce the process has been carried out, increasing the scale to a capacity of 50L. Providers have been contacted and the revision of bids is nearly completed.

Fig. Design of the required technology for the 50 L reactor.

In the meantime, the revision of the laboratory material needed for the test has been performed. Before starting the test on a 50L reactor, the consortium has to be previously adapted to the PCB in flasks of 250ml, increasing the volume progressively, being the previous volume to the 50L-reactor a 10L-reactor already owned by INATEC. This reactor, equipped with sensors and agitation, has been checked and the reagents and material required for working with microorganisms have been listed.

Fig. Test performed in the 10 L reactor in order to check the performance.

B2.1. SUPPLY/SAMPLE PREPARATION

Processing PCBs includes several steps of crushing and separation until a non-metallic fraction to test by bioleaching technology is obtained. Next figure shows the three steps of the global

process where the material has to pass until the final fraction is achieved:

Figure 1. Material through each step of the process.

1st STEP: The process begins with the crushing of the material in a shredder.

2nd STEP: The material is introduced in the mill during continuous cycles.

3rd STEP: The aim of this step is to separate the metallic fraction from the non-metallic one.

MATERIAL FOR BIOLEACHING: The non-metallic fraction obtained in the previous step is the one selected to be used in the bioleaching process that will be carried out by BIOTAWEE consortium.

B1. Optimisation of bioleaching process.

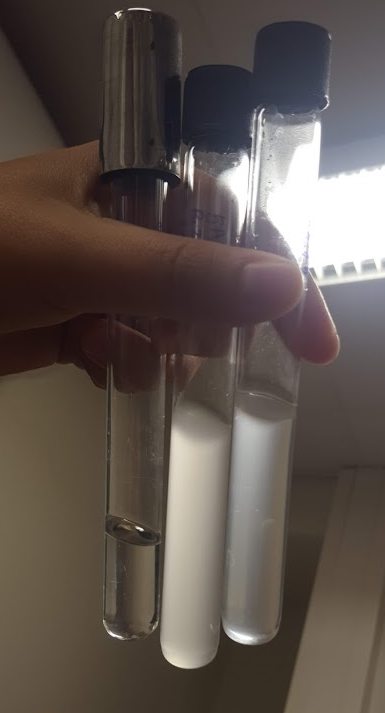

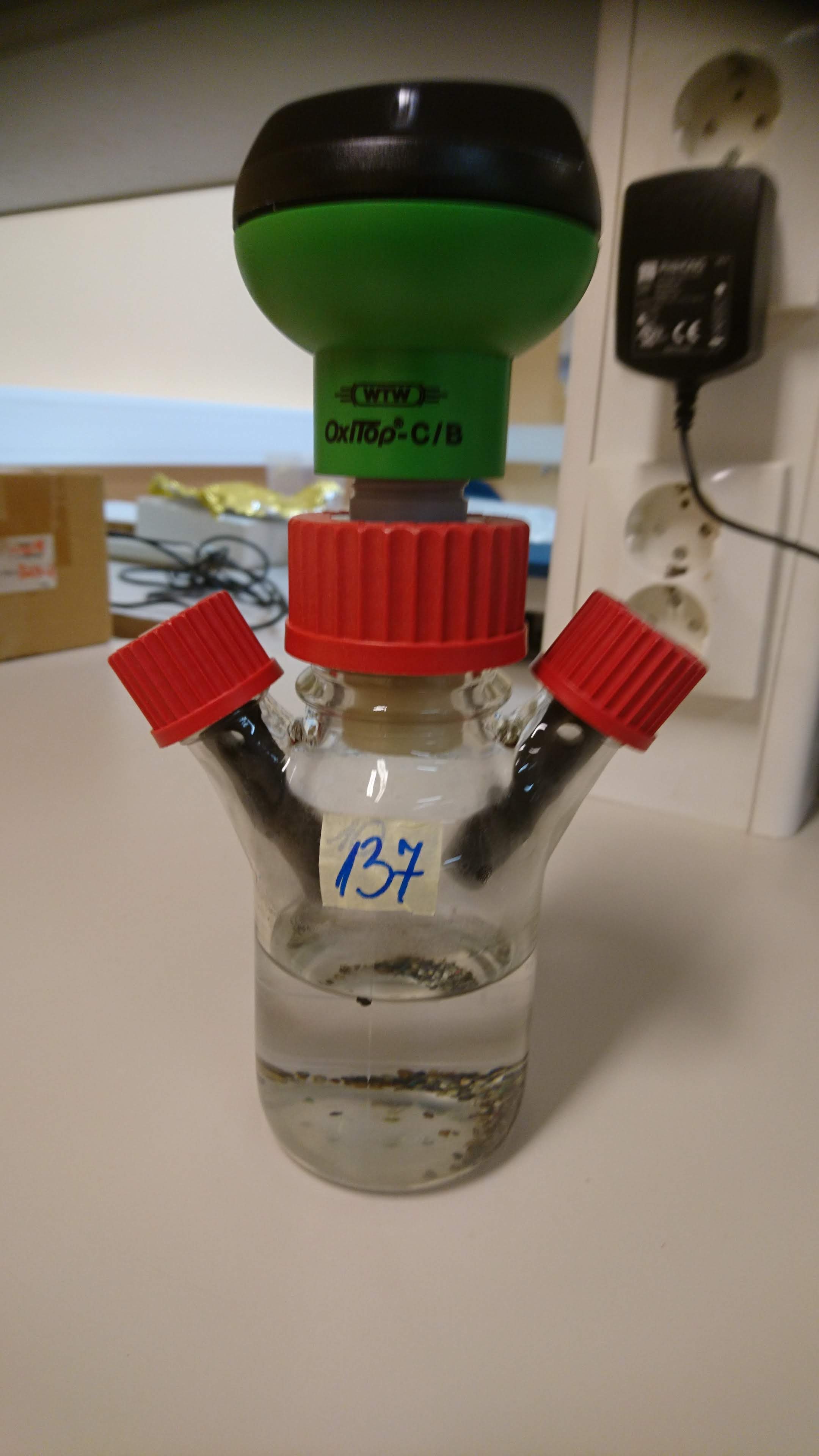

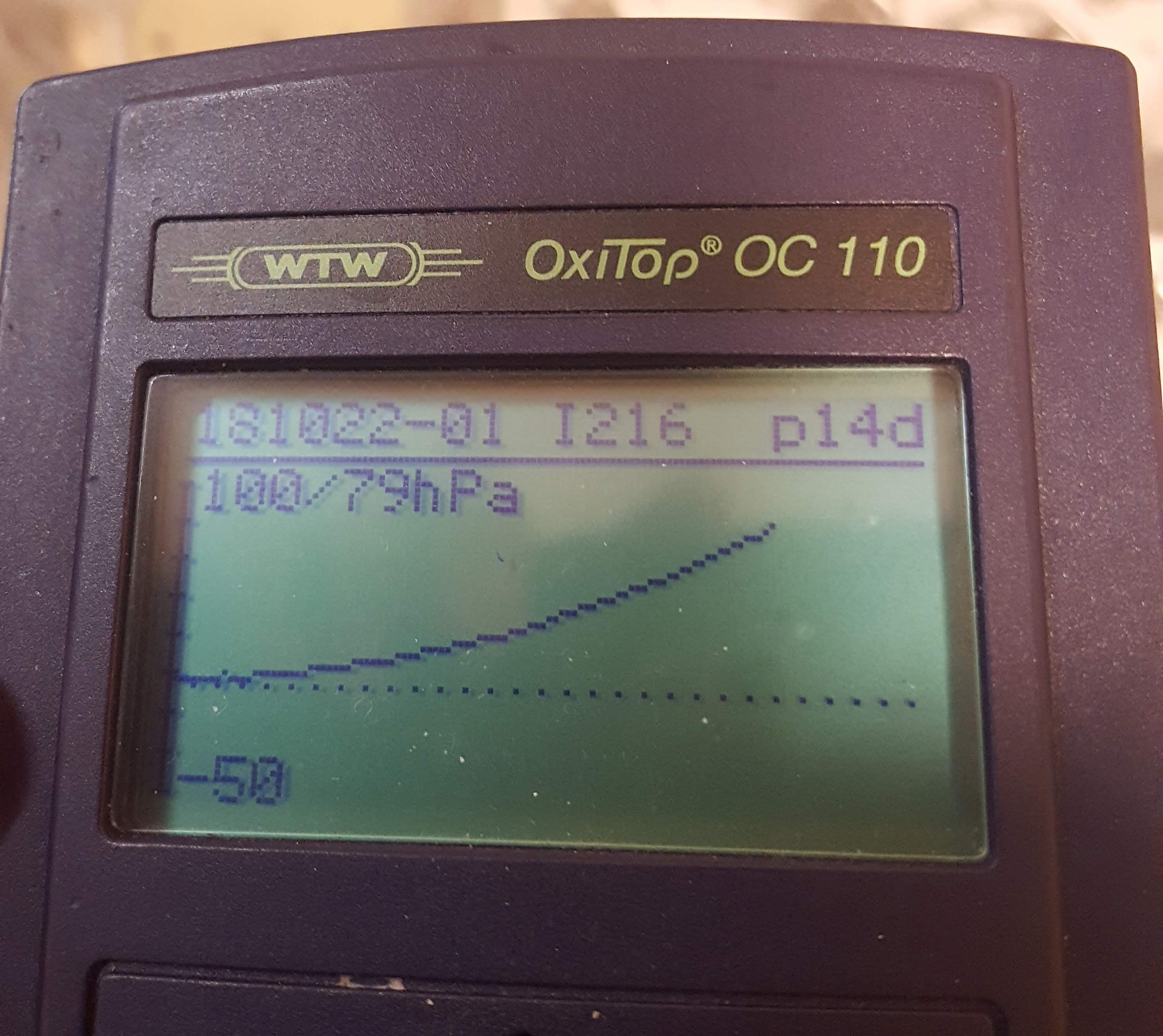

Different bioleaching tests will be carried out with WTW OxiTop systems and Erlenmeyer flasks with conditions and waste stream selected in task 1 in order to perform bench scale tests at 20 L.

A1. Feasibility study.

Photo by S. Sipp Kulli.

Photo by S. Sipp Kulli.

Photo by A. Menert.

Photo by A. Menert.