A1. Feasibility study. (4)

Selection and characterization of specific wastes from REYDESA to be bioleached (origin, shape, suitable pretreatments, etc.) and study on possibilities to use available waste streams from nearby other industries for nutrients solution.

A1.1. Preparation of inoculum for the bioleaching cultivation experiments.

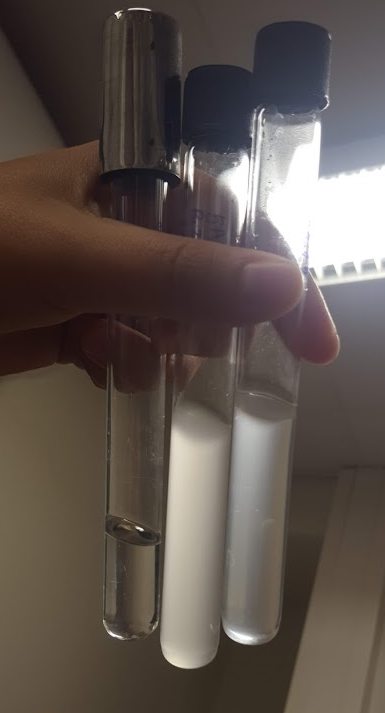

Before placing into the bioleaching experiment, the Inoculum CELMS No EEUT ARGCON5 is pre-cultivated in test tubes in a thermostated shaker at t=37°C.

Photo by S. Sipp Kulli.

After pre-cultivation the remarkable haze in test tubes with inoculum demonstrates the growth of bacteria.

Photo by S. Sipp Kulli.

The BiotaTec coworkers of Kärt Ukkivi, MSc and Anne Menert, PhD are examining the quality of inoculum CELMS No EEUT ARGCON5. The Inoculum has grown up and is ready to be added to the non-metallic fraction of PCBs of WEEE.

Photo by S. Sipp Kulli.

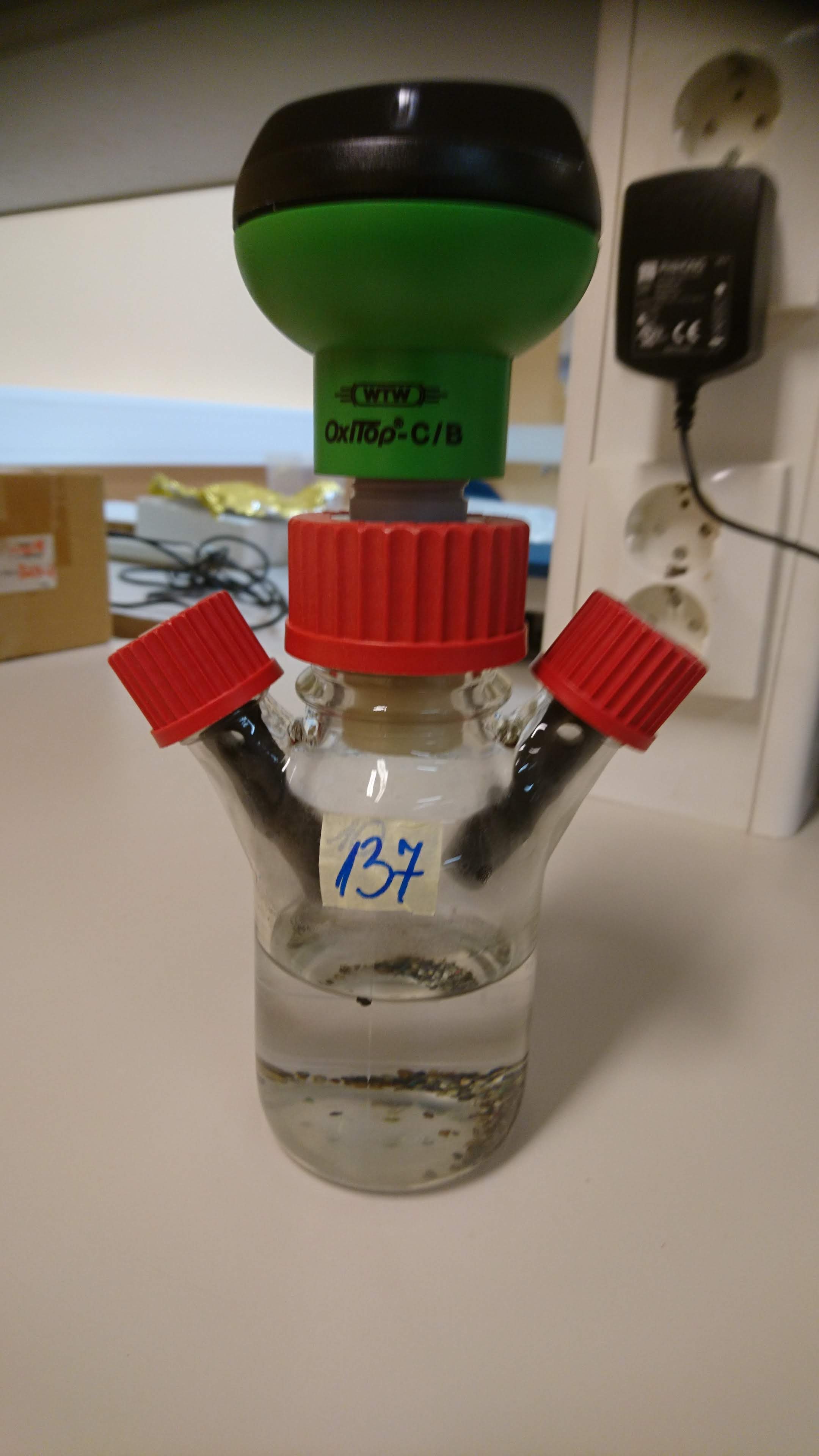

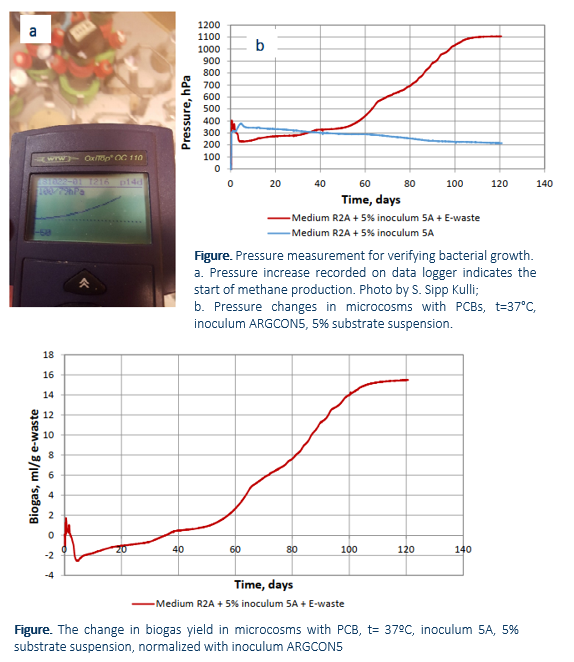

A1.2. Study of microbial biodegradation potential of indigenous species of ARGCON5 with bioleaching cultivation experiments in microcosms with OxiTop AN measuring system.

The flasks of OxiTop AN measuring system with PCBs of WEEE in growth medium inoculated with ARGCON5 and with growth medium and inoculum, 100th day of experiment. The flask with PCBs of WEEE is remarkably darker.

Photo by A. Menert.

The flasks of OxiTop AN measuring system with PCBs of WEEE in growth medium inoculated with ARGCON5 adapted to e-waste, with growth medium and inoculum only and with PCBs of WEEE in growth medium (without inoculum), 10th day of experiment. In the flask with all components added, gas bubbles indicate degradation of organic matter.

Photo by A. Menert.

A1.3. Principal scheme for microbiological treatment of PCBs of WEEE.

Photo by A. Menert.

Photo by S. Kuuse.

Photo by S. Kuuse

A1.4. Analysis of metals content, number of microorganisms and pH

Culture media with suspension of PCBs in reactor flasks were sampled for liquid phase to determine the metal content by ICP-MS method. The initial yields of metals were moderate as the consortium had not yet been adapted to the material (substrate). On the same days, samples were taken from cultivation media for enumeration and identification of microorganisms. Samples were centrifuged (5000 rpm, 10 min) to separate the biomass of microorganisms, from which in turn the DNA was isolated.

The enrichment of microbial consortium from e-waste was successful as the number of microorganisms at the end of the experiment was comparatively high (107 CFU/ml,). The pH of the cultivation medium was in the range facilitating the growth of methanogens; however, several metals are in the form insoluble compounds at this pH (pH 8.5), being the majority of metals leached only in the second, acidophilic phase.

In the current activity the applicability of consortium ARGCON5 for the use with PCBs of WEEE was proved. It was possible to enrich a methane producing microbial community from e-waste. Although the initial methane yield and metals extraction ability were modest, they can be improved in further steps with modifying the medium and by means of adaptive laboratory evolution (Action B1).

© Copyright 2019 - Designed by COASER IT